Autovea

Metalplast Bearings

About Autovea Metalplast

AUTOVEA is committed to manufacturing best-in-class and global quality products that are accurate, precise, economical in cost, and sustainable and socially responsible.”

AUTOVEA’s aim is to strive to meet and exceed our customer’s expectations. Customer delight is our mantra and concern for the environment is our first priority. Our core values which we measure ourselves in the way we do business on a day-to-day basis are-

We Certified by

Our Main Moto

AUTOVEA’s aim is to strive to meet and exceed our customer’s expectations. Customer delight is our mantra and concern for the environment is our first priority. Our core values which we measure ourselves in the way we do business on a day-to-day basis are-

Integrity

Do what is right without compromise. We saw what we mean and do what we say. We act with unconditional honesty, respect, and courtesy at all times

Relationships

We build trusted relations with ow’ customers, suppliers, and each other. We are responsive, transparent, open, and committed to ow·teammate’s success.

Aligment

We share a common goal and succeed as a team.

Can-Do Attitude & Accountability

We expect a·can-do” attitude from ourselves. We believe inaccepting responsibility and the consequences, taking ownership while embracing common goals, and teamwork—and collaborative decision-making.

Empowerment

Everyone has the responsibility and authority to do their job effectively and is encouraged to suggest a better way.

Quality and Innovation

At AUTOV EA, it denotes a commitment to excellence and superior outcomes and is reflected in our products, services, employees, and business practices.

Our Quality Assurance

Computerized Torque Testing

3D Modelling for Mold & Race Profile

Metalurgical Lab Hardness & Microstructure

Surface Finish Checking of RACES

Sound Testing by Decible Meter

What is a suspension strut bearing?

Because of its role the suspension strut bearing has a number of demands placed upon it. If the top mount bearing has a too high friction this can lead to stick-slip behaviour: showing itself as jerky movements and vibrations for those traveling in the vehicle. From a performance perspective a low but constant friction (or torque) is needed, allowing the system to move with no stick-slip or juddering. It is also used to transmit the suspension loads to the chassis: this has to be accommodated in the bearing design.

The suspension strut sub-system is reliant upon the suspension strut bearing to offer a smooth ride over the lifetime of the vehicle.

From absorbing road impact to facilitating movement, the suspension strut and the bearing provide vehicle users with a smooth ride.

The suspension strut plays a pivotal role in how the car handles. This simple yet hugely important part can have an enormous impact on how end users, both drivers and passengers, perceive the ride quality of the car and consequently the overall quality of the vehicle.

The suspension strut consists of the suspension spring coil and damper and it connects the axle to the car body. When the vehicle is traveling the coil compresses and extends absorbing the impact from road, the damper controls the movement by limiting the spring oscillation. To facilitate this process, the coil needs to pivot and rotate, it is the suspension strut bearing that enables this movement against the static top mount.

Suspension Bearings

Design

Torque Testing

Sound Testing

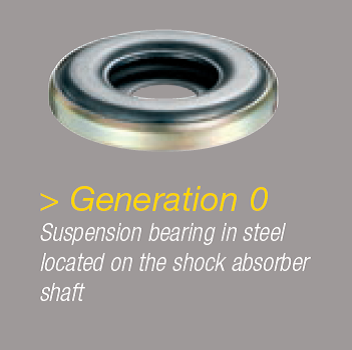

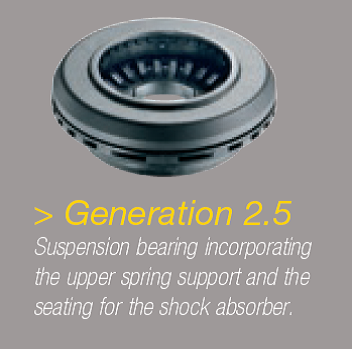

Evolution of the Macpherson Suspension Bearing

Happy Customers

“Best bearing manufacturers in Mysore. More reliable and efficient to fulfill the customer’s needs. In one source u can get complete industrial solution.”

“Knowledgeable dealers and really good products sold by this place. I Would highly recommend Autovea for any of your bearing needs.”